Key points of automatic visual positioning dispensing robot

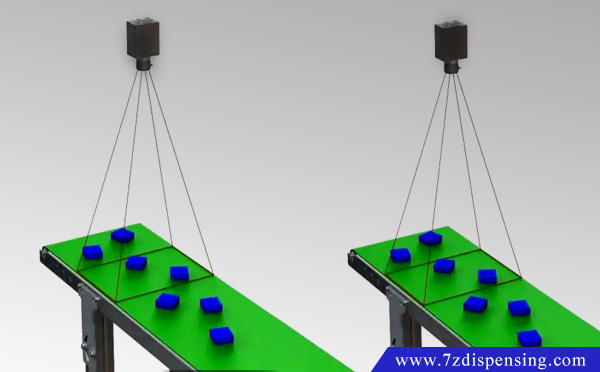

As an automatic equipment, the automatic visual positioning dispenser is widely used in many factories because of its high working efficiency, simple operation and the ability to replace the current labor shortage. What factors affect the dispensing process of the automatic visual positioning dispensing robot?

1. The longer the dispensing time is, the greater the amount of glue will be, and vice versa. For non quantitative requirements, the size of the glue point diameter is half of the product diameter, which can ensure that there is enough glue to bond all parts and avoid glue waste.

2. The viscosity of glue, the higher the viscosity, the worse the fluidity, and the greater the regulating pressure required by the distributor.

3. If there are many rubber bubbles, vacuum pump shall be used for vacuum treatment first, and then the dispensing machine shall be used for dispensing to ensure the quality of dispensing products.

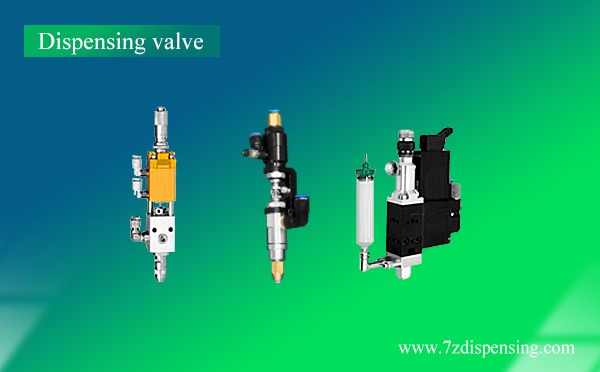

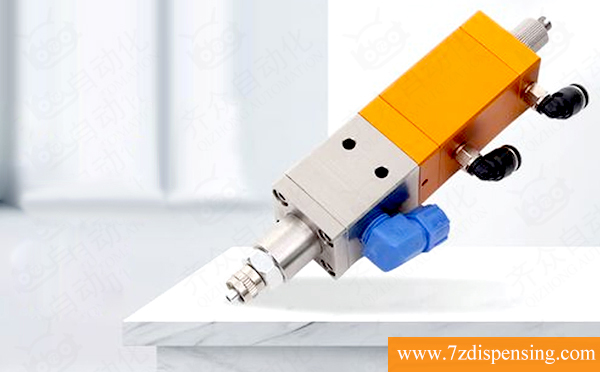

4. According to the dispensing process requirements and glue properties, it is reasonable to choose the dispensing valve or syringe or other glue control systems. If the requirements are relatively high and the glue is relatively thin, the dispensing valve should be selected better than the syringe. The valve has a good suction back effect, which can ensure no glue leakage. For the sticky glue, the dispensing valve has a better gel collection effect than the syringe, which can solve the wire drawing problem. For the products with moderate viscosity of glue and low requirements, the needle cylinder can be selected. The cost is relatively low and can meet the requirements of dispensing.

5. Strictly follow the temperature curve given by the glue manufacturer and the products after glue curing.

6. The needle head shall be selected reasonably. The best effect is that the diameter of the needle head is half of the diameter of the glue point. For the corrosive glue, the teflon needle head shall be selected. For the ultraviolet glue, the needle barrel and needle head with ultraviolet shielding shall be selected.

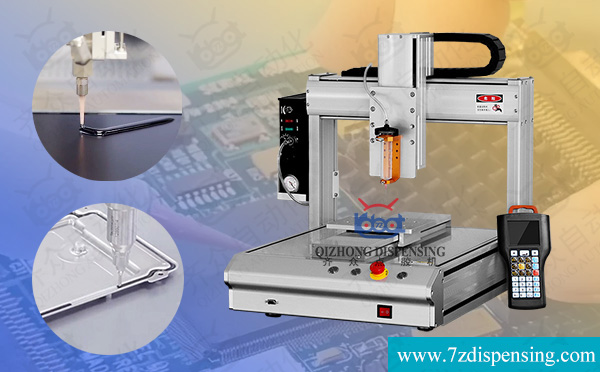

Automatic visual positioning dispensers are widely used in various fields, such as semiconductor, electronic components, etc. It happens that these fields have high requirements for the production process of the automatic visual positioning dispenser, so how to effectively ensure the dispensing accuracy of the automatic visual positioning dispenser? Today, Qizhong Dispenser told us how to ensure the automatic visual positioning dispensing accuracy of the dispenser.

Dispensing size and glue viscosity setting:

In general, the dispensing amount should be half of the product spacing, so that each component has enough glue to bond without excess glue overflowing, making the dispensing speed of the automatic dispenser faster and more accurate. The viscosity of glue is high and the glue point is small, which is easy to lead to wire drawing. The viscosity of glue is low and the glue point is large, which may lead to the phenomenon of glue percolation dyeing products. Therefore, it is very important to select the appropriate glue viscosity for the automatic dispenser.

Setting of dispensing needle and dispensing pressure: The selection of full-automatic visual positioning dispensing needle shall be based on the product size and dispensing diameter. Generally, the size of the dispensing needle of the automatic visual positioning dispenser should be half of the size of the dispensing point. Too much of the dispensing needle will cause glue overflow and affect the dispensing accuracy. However, too much dispensing pressure will cause glue overflow, and too little pressure will cause leakage or intermittent dispensing. Therefore, the dispensing process required by the product cannot be met, resulting in low product qualification rate and low work efficiency.

The distance between the dispensing machine needle and the working surface is set, and the dispensing needles used by different automatic visual positioning dispensing machines are different. Some needles have a certain degree of braking effect, while others do not. Therefore, it is important to master the dispensing interval between the needle and the working surface. Moreover, the distance between the needle and the working surface should be calibrated before dispensing each time.

keywords: Dispensing-MachineVisual-dispensing-machineVisual